Table of Contents

丙烯酸扩散器中使用的材料

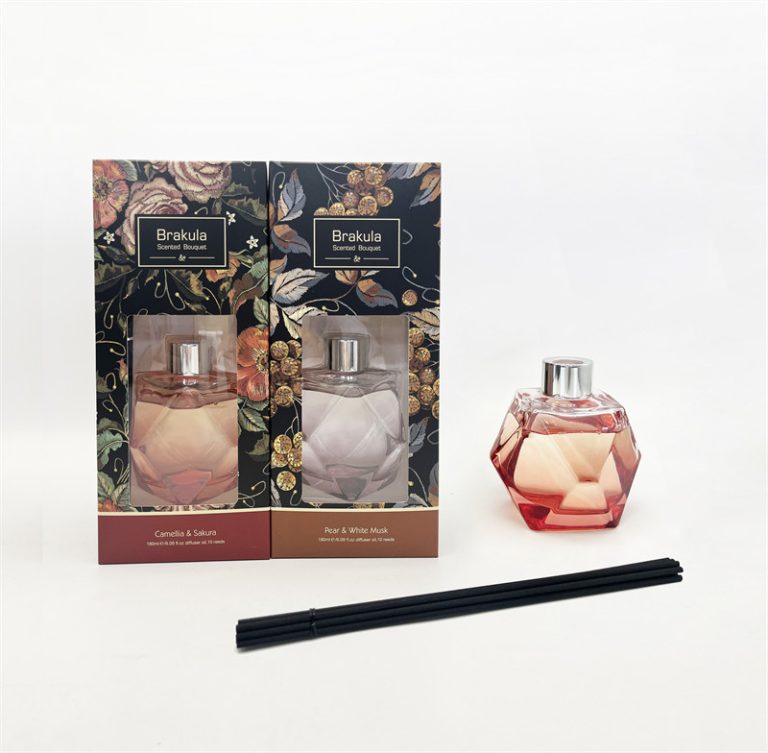

丙烯酸扩散器的另一个重要方面是其生产中使用的添加剂。这些包括紫外线稳定器,可帮助保护丙烯酸在暴露于阳光下随着时间的推移泛黄。此外,一些制造商还融合着着色剂,以生产各种颜色的扩散器,从而使设计具有美观的灵活性。

https://reedaromalab.com/tag/high-quality-diffuser-sets-suppliers名称

| 室内芳香疗法 | materials |

| 金属 | 适合 |

| basement | 气味 |

| 茶花和樱花,粉红色的葡萄柚 | Accition |

| 250ml | Color |

| Indigo | Origin |

| 中国批发商 | 期限 |

| 90-120天 | 制造过程 |

扩散器设置自定义

丙烯酸扩散器的产生通常始于丙烯酸片的挤压或铸造。在挤出过程中,将丙烯酸颗粒加热到融化,然后通过模具强迫创建特定厚度的表。该方法有效地生产大量均匀的床单。制造商可以使用CNC机器或激光切割机来实现精确的尺寸和复杂的设计。这个阶段至关重要,因为它允许根据单个客户的规格或设计要求进行自定义。此步骤对于实现所需的美学和功能特性至关重要。最终产品通常会用涂层来治疗,以提高抗刮擦性并进一步增强扩散器的寿命。

质量控制和测试 质量控制在丙烯酸扩散器的生产中起着重要作用。每批丙烯酸板都经过测试,以确保清晰,强度和抗紫外线。制造商实施了严格的标准,以确保每个扩散器都符合行业的要求和客户期望。

除了视觉检查外,还进行了物理测试以评估扩散器的耐用性。这些测试可能包括冲击电阻和热稳定性检查。通过确保生产期间的高标准,制造商可以最大程度地减少缺陷并提高整体产品可靠性。适当的处理和包装对于防止运输过程中的损坏至关重要,确保客户在原始状态下收到其产品。

Quality Control and Testing

Quality control plays a significant role in the production of acrylic diffusers. Each batch of acrylic sheets is tested for clarity, strength, and resistance to UV light. Manufacturers implement rigorous standards to ensure that every diffuser meets industry requirements and customer expectations.

In addition to visual inspections, physical tests are conducted to assess the durability of the diffusers. These tests may include impact resistance and thermal stability checks. By ensuring high standards during production, manufacturers can minimize defects and improve overall product reliability.

Finally, once the diffusers have passed quality checks, they are prepared for packaging and distribution. Proper handling and packaging are essential to prevent damage during transport, ensuring that customers receive their products in pristine condition.