Table of Contents

The Materials Used in Acrylic Diffusers

Acrylic diffusers are primarily made from a type of plastic known as polymethyl methacrylate (PMMA). This material is favored for its clarity, durability, and lightweight properties. PMMA can be easily molded into various shapes and sizes, making it an ideal choice for manufacturers who want to create customized diffusers.

https://reedaromalab.com/tag/high-quality-diffuser-sets-suppliersAnother important aspect of acrylic diffusers is the additives used in their production. These include UV stabilizers that help protect the acrylic from yellowing over time when exposed to sunlight. Additionally, some manufacturers incorporate colorants to produce diffusers in various colors, allowing for aesthetic flexibility in design.

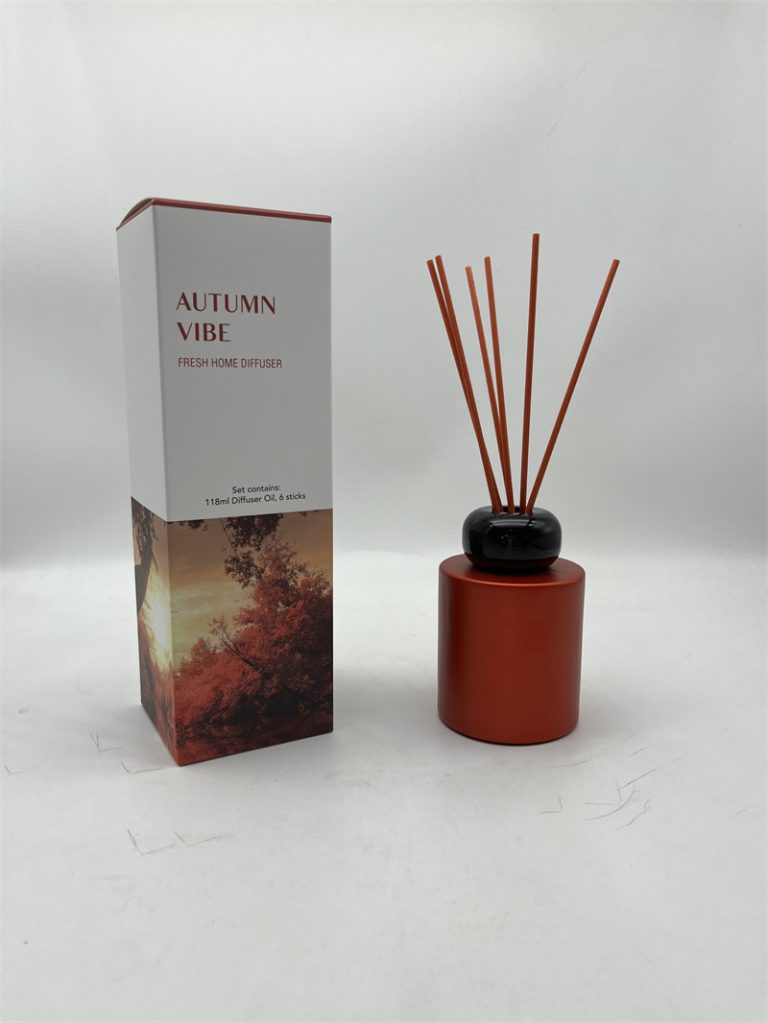

| Name | Indoor Aromatherapy |

| Material | Metal |

| Suitable for | Basement |

| Scents | Camellia & Sakura, Pink Grapefruit |

| Capacity | 250ml |

| Color | Indigo |

| Origin | China Wholesaler |

| Duration | 90-120days |

The quality of the raw materials directly impacts the performance of the diffuser. High-quality acrylic provides better light diffusion and minimizes hotspots, ensuring that light is evenly distributed throughout the space. This is particularly important in applications such as lighting fixtures and decorative elements.

The Manufacturing Process

Diffuser Sets customization The production of acrylic diffusers typically begins with the extrusion or casting of acrylic sheets. In the extrusion process, acrylic pellets are heated until they melt and then forced through a mold to create sheets of specific thicknesses. This method is efficient for producing large quantities of uniform sheets.

Once the sheets are formed, they undergo a process of cutting and shaping. Manufacturers can use CNC machines or laser cutters to achieve precise dimensions and intricate designs. This stage is crucial, as it allows for customization based on individual client specifications or design requirements.

After shaping, the diffusers undergo polishing to enhance clarity and smoothness. This step is vital for achieving the desired aesthetic and functional properties. The final product is often treated with coatings that improve scratch resistance and further enhance the diffuser’s longevity.

Quality Control and Testing

Quality control plays a significant role in the production of acrylic diffusers. Each batch of acrylic sheets is tested for clarity, strength, and resistance to UV light. Manufacturers implement rigorous standards to ensure that every diffuser meets industry requirements and customer expectations.

In addition to visual inspections, physical tests are conducted to assess the durability of the diffusers. These tests may include impact resistance and thermal stability checks. By ensuring high standards during production, manufacturers can minimize defects and improve overall product reliability.

Finally, once the diffusers have passed quality checks, they are prepared for packaging and distribution. Proper handling and packaging are essential to prevent damage during transport, ensuring that customers receive their products in pristine condition.